C.I. Fluting/Corrugated

C.I. Fluting/Corrugated Specification

- Usage & Applications

- Fluting or corrugating rollers used for corrugated box manufacturing, paper industry

- Load Capacity

- High Load Bearing

- Casting Process

- Sand Casting

- Product Type

- C.I. Fluting/Corrugated

- Material

- Cast Iron

- Surface Finishing

- Polished

- Weight

- Standard/Customized

- Color

- Grey

- Hardness

- Imparted as per requirement (Typically up to 500 HB)

- Corrosion Resistance

- Enhanced with proper surface treatment

- Compatibility

- Compatible with multiple corrugator brands and models

- Length

- Custom lengths as per machine specifications

- Groove Type

- Fluted/Corrugated surface design

- Durability

- Long service life under continuous operation

- Machining Tolerance

- High precision, close tolerance maintained

- Diameter

- Customizable, standard sizes available

C.I. Fluting/Corrugated Trade Information

- Minimum Order Quantity

- 2 Tons

- Supply Ability

- 100000 Tons Per Month

- Delivery Time

- 1 Week

About C.I. Fluting/Corrugated

The offered C.I. Fluted/Corrugated is a mould that is used in many industries. Made with unmatched quality cast iron, the mould has a long service life and is extremely durable, also it requires no extra maintenance cost. This is offered by us at absolutely reasonable price and is highly praised by customers all over the world for its performance. The C.I. Fluted/Corrugated is a highly reliable mould that can be used for any type of metal including aluminium, brass steel etc.

This process has gained popularity based on the superior quality of the castings produced. And, more important is the fact that, the cost of a finished component produced by the casting process is less than or comparable to that of the conventional production techniques.

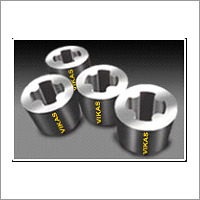

Our product range consists of the following:

13.5 x 16.5 x 62 (419mm)

17 x 19 x 72 (522mm)

19 x 21 x 65 (522mm)

21 x 23 x 65 (572mm)

23 x 26 x 65 (715mm)

12 x 15 x 53(M-1 Hexagonal Plug)

14 x 17 x 53 (M-1.5 Plug)

16 x 17 x 58 (M-2 Plug Corr)

19 x 21 x 57 (M-2.5 Plug Corr)

24 x 28 x 48 (BSO BF Polygonal)

21 x 24 x 62 (M-3 BSO Polygonal)

28 x 32 x 58 (M-4 BSO 6F Polygonal)

28 x 31 x 58.7 (M-5 BSO 12F Polygonal)

28 x 32 x 59 (M-6 BSO 12F Polygonal)

804 x 977 x 1860mm (M-9 BSO 12F)

22 x 24 x 65 (BSO Corrugated)

23 x 26 x 70 (BSO Corrugated)

19 x 22 x 56 (BSO Corrugated)

16 x 19 x 62 (BSO Corrugated)

N.B.: Plug type, Non-Plug type, Fluted / Corrugated Mould of any sizes are also available.

High-Performance Fluting Rollers for Every Application

Our C.I. Fluting and Corrugated rollers boast customizable dimensions and surface patterns to precisely match your machine specifications. Designed for high endurance and exceptional load capacity, these rollers improve efficiency in corrugated box and paper manufacturing even under 24/7 operation.

Premium Materials and Advanced Casting Techniques

Each roller is constructed from either ductile or cast iron using advanced sand casting methods. This ensures robust mechanical strength, enhanced durability, and the ability to withstand heavy operational demands with a polished and corrosion-resistant finish.

Tailored Precision for Industry Needs

From high precision close machining tolerance to custom surface finishing and corrosion resistance, every aspect of our rollers is tailored for reliability and adaptability. Suitable for diverse machinery, they offer seamless compatibility with leading corrugator brands and models.

FAQs of C.I. Fluting/Corrugated:

Q: How are the hardness and durability of these fluting/corrugated rollers ensured?

A: The rollers are engineered to achieve hardness up to 500 HB, tailored as per customer requirements. Their durability is further enhanced through material selection (ductile or cast iron) and advanced surface treatment, supporting continuous operation with a long service life.Q: What is the typical process for customizing diameter and length?

A: Customers can specify their required diameter and length based on their machine specifications. Standard and customized sizing is available, ensuring optimal integration with most corrugator models and production lines.Q: When should I choose a fluted versus a corrugated surface roller?

A: Fluted surfaces are ideal for forming crisp and accurate flutes in corrugated sheets, while corrugated designs cater to different flute profiles or structural requirements. The choice depends on your intended box quality and machinery setup.Q: Where can these rollers be used?

A: These rollers are widely used in corrugated box manufacturing plants, paper industries, and facilities engaged in exporting, manufacturing, or supplying packaging materials. They suit environments requiring high throughput and reliability.Q: What are the benefits of the sand casting process used?

A: Sand casting enables the creation of complex shapes with precise tolerances, resulting in rollers that offer high strength, consistency, and customizable features. This process supports large and small batch production alike.Q: How does the enhanced corrosion resistance contribute to roller performance?

A: Proper surface treatments and polishing significantly reduce wear and susceptibility to rust, thereby extending the lifespan of the rollers even in high-humidity or demanding manufacturing environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cast Iron Products Category

Cast Iron Guide

Price Range 40.00 - 80.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Color : Dark Grey

Casting Process : Sand Casting / Lost Foam Casting

Weight : 2 to 10000 Kilograms (kg)

Surface Finishing : Polished

Cast Iron Counter Weight

Price Range 50.00 - 80.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Color : Grey / Black (customized on request)

Casting Process : Sand Casting / Gravity Casting

Weight : 5 kg 2000 kg

Surface Finishing : Other, Smooth Painted Finish

Cast Iron Coupling

Price Range 40.00 - 80.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Color : Dark Grey / Black

Casting Process : Sand Casting

Weight : Approx. 1.5 3.5 kg (varies by size)

Surface Finishing : Other, Rust Resistant Coated

Cast Iron Sinter Baking Pan

Minimum Order Quantity : 2 Tons

Color : Black/Grey

Casting Process : Sand Casting

Weight : Approx. 34 kg

Surface Finishing : Other, Sintered Coating

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry