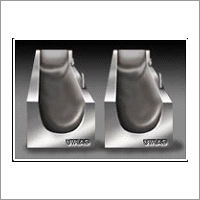

Cast Iron Arch Bar

Cast Iron Arch Bar Specification

- Usage & Applications

- Railway Track Construction, Structural Engineering, Support Frameworks

- Casting Process

- Sand Casting

- Load Capacity

- High (Suitable for Heavy Load Applications)

- Product Type

- Arch Bar

- Material

- Cast Iron

- Surface Finishing

- Smooth Painted or Natural Finish

- Weight

- Varies as per Size and Design (Typically 10-30 kg)

- Color

- Grey or Black

- Temperature Resistance

- Suitable for High and Low Temperature Environments

- Dimension

- Customizable (Standard Lengths and Widths Available)

- Shape

- Curved/Arch Bar

- Tensile Strength

- At least 200 MPa

- Hardness

- 170-230 HB

- Service Life

- Long Service Life in Heavy Duty Operations

- Corrosion Resistance

- Enhanced with Surface Treatment

- Standards Complied

- IS: 210, ASTM A48 or Equivalent

- Installation Method

- Bolted or Welded as per Requirement

Cast Iron Arch Bar Trade Information

- Minimum Order Quantity

- 2 Tons

- Supply Ability

- 100000 Tons Per Month

- Delivery Time

- 1 Week

About Cast Iron Arch Bar

Cast Iron Arch Bar provided by us, is therefore perfect for a variety of industrial applications, such as pulleys, gears, wheels, and pistons. Machinability, sliding wear resistance, heat treat response, noise and vibration damping qualities are all advantages of cast iron bar and plate. Arrow slits were made using iron bars. Cast Iron Arch Bar is very easy to install as well as simple to use. When put between a door and a solid block, iron bars, like glass panes and fences, can be used to create small gaps.Exceptional Performance in Demanding Environments

Cast Iron Arch Bars are specifically designed to withstand high-stress and high-wear environments. Their robust construction and temperature resistance make them suitable for use in both extremely hot and cold conditions, providing longevity and reliability for heavy-duty operations such as those found in railway and structural engineering projects.

Versatile Applications and Customizable Solutions

Our arch bars come in a variety of standard and custom dimensions, supporting diverse applications in railway construction, support frameworks, and structural engineering. The flexibility in design and surface finish options ensures the perfect fit for a wide range of industrial requirements, backed by compliance with international standards.

FAQs of Cast Iron Arch Bar:

Q: How can Cast Iron Arch Bars be installed on-site?

A: Cast Iron Arch Bars can be easily installed using either bolting or welding methods, as per project requirements. This flexibility accommodates different structural needs and facilitates straightforward integration into various frameworks and railway tracks.Q: What benefits does the surface treatment provide for these arch bars?

A: The advanced surface treatment enhances corrosion resistance, helping the arch bars endure harsh environmental conditions and extending their operational life, even in high humidity or exposure-prone settings.Q: When should I consider customization for Cast Iron Arch Bars?

A: Customization is recommended when your project has unique size or load requirements, or when standard dimensions do not fit your application. We offer custom lengths and widths to ensure optimal compatibility and performance.Q: Where are these arch bars typically used?

A: These arch bars are extensively used in industrial applications such as railway track construction, structural engineering, and support frameworks, where high strength and durability are essential.Q: What casting process is used for manufacturing these arch bars?

A: Our Cast Iron Arch Bars are manufactured using the sand casting process, which enables precise shaping and high structural integrity suitable for heavy-duty and high-load applications.Q: Which international standards do these arch bars comply with?

A: The arch bars meet or exceed IS: 210 and ASTM A48 standards, ensuring consistent quality, mechanical strength, and performance in diverse industrial environments.Q: How does using Cast Iron Arch Bars benefit my project?

A: Utilizing these arch bars guarantees enhanced load capacity, reliable long service life, and resistance to both corrosion and temperature fluctuations, making them a safe and cost-effective choice for critical infrastructure projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cast Iron Products Category

Cast Iron Ring

Price Range 40.00 - 80.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Color : Grey or Black

Surface Finishing : Other, Smooth, AntiRust Coating

Casting Process : Sand Casting

Usage & Applications : Heavy Machinery, Industrial Equipment, Automotive, Construction

Cast Iron Pulley

Price Range 40.00 - 80.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Color : Grey/Black

Surface Finishing : Other, Smooth Painted/Polished

Casting Process : Sand Casting

Usage & Applications : Used in Elevators, Mechanical Drives, Agricultural Machinery, and Conveyor Systems

Cast Iron Bottom Plate

Price Range 40.00 - 80.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Color : Grey

Surface Finishing : Other, Smooth Machined

Casting Process : Sand Casting

Usage & Applications : Machinery base plate, construction support, industrial equipment mounting

Cast Iron Launder

Minimum Order Quantity : 2 Tons

Color : Dark Grey / Black

Surface Finishing : Other, Rough and Unpainted

Casting Process : Sand Casting

Usage & Applications : Transporting molten metal in foundries and metallurgical plants

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry