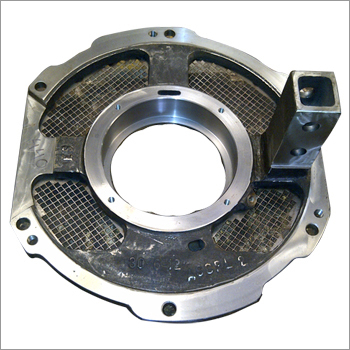

Cast Iron Coupling

Cast Iron Coupling Specification

- Process

- Casting

- Surface Treatment

- Galvanized / Painted

- Product Type

- Pipe Coupling

- Material

- Cast Iron

- Surface

- Smooth

- Dimension (L*W*H)

- Varies as per size (e.g. 50mm x 60mm x 80mm)

- Size

- 1/2 inch to 6 inch

- Weight

- 0.2 kg 5 kg (depending on size)

- Application

- Pipe fitting and plumbing connections

- Color

- Black / Silver Grey

- Pressure Rating

- Up to 25 Bar

- Connection

- Screwed or Socket Weld

- Corrosion Resistance

- High

- Temperature Range

- -10°C to 220°C

- Standard

- IS 1879 / ASTM A197

- Usage

- Industrial, Agricultural, Water Supply

- End Type

- Female Threaded

Cast Iron Coupling Trade Information

- Minimum Order Quantity

- 2 Tons

- Supply Ability

- 10000 Tons Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- As Per Buyers Requirement & Order

- Main Domestic Market

- All India

About Cast Iron Coupling

Reliable Pipe Connections for Demanding Environments

The Cast Iron Coupling guarantees secure and leak-proof joints for pipe systems in diverse sectors, including agriculture, water supply, and industry. Its high-pressure and wide temperature tolerance, coupled with robust corrosion resistance, make it ideally suited for tough operational settings. Each piece undergoes precision casting and finishing, giving a smooth surface and extended service life.

Standards Compliance and Versatile Installation

Our couplings strictly adhere to IS 1879 and ASTM A197 standards, ensuring international compatibility and safety. They are engineered for easy installation through screwed or socket weld connections, accommodating a wide range of pipe fitting requirements. With multiple sizes and finishes available, customization for specific projects is simple and efficient.

FAQs of Cast Iron Coupling:

Q: How do I install a Cast Iron Coupling with a female threaded end?

A: You can install the coupling either by screwing it onto a matching male threaded pipe or by using socket welding for compatible systems. Ensure pipe ends are clean and appropriately prepared for a secure and leak-free fit.Q: What are the benefits of using cast iron couplings in industrial and agricultural settings?

A: Cast iron couplings provide high corrosion resistance, withstand substantial pressure up to 25 Bar and temperatures from -10C to 220C, and offer exceptional durability, making them reliable for demanding applications where longevity is critical.Q: Where are cast iron couplings commonly used?

A: These couplings are commonly used in industrial installations, agricultural pipeline networks, and various water supply projects due to their robustness and adaptability to different environmental conditions.Q: What is the manufacturing process for these cast iron couplings?

A: The couplings are manufactured through a casting process, followed by surface treatments like galvanization or painting. This ensures smooth finishes and enhances their corrosion resistance for prolonged service.Q: When should I choose socket weld over screwed connections for cast iron couplings?

A: Socket weld connections are preferred when a stronger, permanent joint is required, especially in high-pressure or vibration-prone systems. Screwed connections are suitable for installations where future dismantling or maintenance is expected.Q: What sizes and weights are available for cast iron couplings?

A: Cast iron couplings are available in sizes ranging from 1/2 inch to 6 inch, with weights depending on sizetypically between 0.2 kg and 5 kg.Q: Does the surface treatment on the coupling affect its performance or durability?

A: Yes, galvanizing or painting the surface significantly enhances corrosion resistance and longevity. The smooth finish also facilitates easier installation and maintenance, improving overall performance in harsh conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Castings Category

Cast Iron Wedge

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Color : Grey / Black

Product Type : Other, Wedge

Surface Treatment : Polished

Dimension (L*W*H) : 150 mm x 40 mm x 25 mm

Steel Casting PE Bracket

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Color : Metallic Grey

Product Type : Other, PE Bracket

Surface Treatment : Other, Hot Dip Galvanized

Dimension (L*W*H) : 150 mm x 80 mm x 50 mm

Steel Casting Male Clutch

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Color : Metallic Silver

Product Type : Other, Male Clutch

Surface Treatment : Polished

Dimension (L*W*H) : Customized as per drawing

Steel Casting Anode Bracket

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Color : Metallic Grey

Product Type : Other, Anode Bracket

Surface Treatment : Other, Hot Dip Galvanized

Dimension (L*W*H) : Customizable

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry