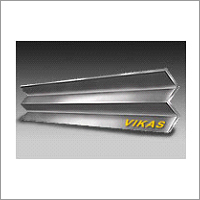

Cast Iron Rail

Cast Iron Rail Specification

- Load Capacity

- 350 kg

- Usage & Applications

- Rail track construction, industrial guidance systems

- Casting Process

- Sand Casting

- Product Type

- Cast Iron Rail

- Material

- High Grade Cast Iron

- Surface Finishing

- Smooth/Polished

- Weight

- 12 kg (Approximate)

- Color

- Black/Grey

- Hardness

- 180-220 HB

- Grade

- FG 260 / EN-GJL-260

- Corrosion Resistance

- Good, suitable for outdoor use

- Tensile Strength

- 250 MPa (Minimum)

- Length

- 1100 mm

- Width

- 110 mm

- Height

- 75 mm

- Machinability

- Excellent

Cast Iron Rail Trade Information

- Minimum Order Quantity

- 2 Tons

- Supply Ability

- 100000 Tons Per Month

- Delivery Time

- 1 Week

About Cast Iron Rail

We are one of the leading companies in the production of Cast Iron Rail which are made of cast iron and customised to the specifications and measurements of the client. This is made in such a way that they may easily be integrated into glass creations. It is available in a range of attractive styles. Cast Iron Rail is suitable for use on both residential and commercial structures. We also carry out a variety of quality control measures to ensure that they comply with established industry standards.

Engineered for Durability and Performance

Manufactured from premium-grade cast iron (FG 260 / EN-GJL-260), this rail is built to endure demanding environments. Its high tensile strength, robust corrosion resistance, and ability to withstand substantial loads guarantee reliable performance even in outdoor or industrial settings. The smooth surface finish minimizes friction, enhancing guidance system efficiency.

Versatile Applications

Ideally suited for rail track construction and as a component in industrial guidance systems, this cast iron rail can also be customized for other engineering projects. The combination of machinability, strength, and corrosion resistance ensures suitability across various industries, offering flexibility for designers and engineers.

FAQs of Cast Iron Rail:

Q: How should the cast iron rail be installed for optimal performance?

A: For optimal results, install the rail on a level, supportive base using appropriate fixings, matching its load capacity of 350 kg. Ensure the smooth or polished surface faces the guidance system for minimal wear and use corrosion-resistant fasteners if exposed to harsh weather.Q: What are the main benefits of choosing FG 260 (EN-GJL-260) grade cast iron for this rail?

A: FG 260 offers excellent strength, durability, and machinability. Its notable corrosion resistance makes it well-suited for both outdoor and high-load industrial applications, while the smooth finish provides reduced friction and extended component lifespan.Q: When is this rail recommended for use in industrial projects?

A: This rail is recommended when high load-bearing capacity, durability, and corrosion resistance are requiredespecially in rail track infrastructure or heavy-duty guidance systems exposed to variable weather or mechanical stresses.Q: Where is the cast iron rail typically manufactured and supplied from?

A: The rail is manufactured and exported from India, where established foundries and suppliers ensure quality through advanced sand casting processes and strict material testing.Q: What casting process is used, and how does it influence performance?

A: The sand casting process is used to produce this rail, allowing for intricate shapes and smooth finishes. This method ensures a robust structure and precise dimensions, resulting in high mechanical strength and refined surface quality suitable for heavy-duty engineering applications.Q: How does the rails corrosion resistance contribute to its lifespan outdoors?

A: Good corrosion resistance protects the rail from rust and environmental degradation, thereby extending its operational lifespan in outdoor or exposed settings and reducing maintenance requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cast Iron Products Category

Cast Iron Pulley

Price Range 40.00 - 80.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Usage & Applications : Used in Elevators, Mechanical Drives, Agricultural Machinery, and Conveyor Systems

Weight : 215 Kg (Varies According to Size)

Surface Finishing : Other, Smooth Painted/Polished

Cast Iron Launder

Price 40-80 INR / Kilograms

Minimum Order Quantity : 2 Tons

Usage & Applications : Transporting molten metal in foundries and metallurgical plants

Weight : 50100 kg (Approx.)

Surface Finishing : Other, Rough and Unpainted

Cast Iron Bottom Plate

Price Range 40.00 - 80.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Usage & Applications : Machinery base plate, construction support, industrial equipment mounting

Weight : Customizable (Typically 2 kg to 50 kg)

Surface Finishing : Other, Smooth Machined

Cast Iron W Channel

Price Range 40.00 - 80.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Usage & Applications : Structural support for heavy machinery, conveyor systems, and architectural frameworks

Weight : Varies by Size (Typically 1560 kg per meter)

Surface Finishing : Other, Smooth Machined Surface

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry