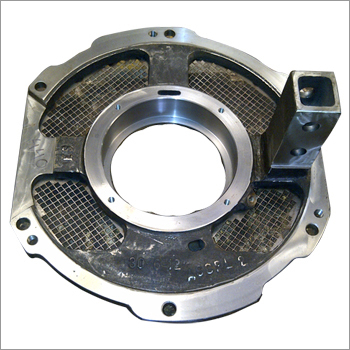

Steel Casting Valve Body

Steel Casting Valve Body Specification

- Surface Treatment

- Polished

- Process

- Investment Casting

- Product Type

- Valve Body

- Material

- Steel

- Surface

- Smooth

- Dimension (L*W*H)

- Customized

- Size

- As per requirement

- Weight

- Varies (Depends on size/design)

- Application

- Industrial Valves

- Color

- Metallic Grey

- Machinability

- Excellent

- Standards

- ASTM, DIN, JIS or as specified

- Feature

- Robust design, Leak proof sealing

- Compatibility

- Suitable for Water, Oil, Gas applications

- Casting Tolerance

- ±0.01 mm

- Corrosion Resistance

- High

- Service Life

- Long life under standard operating conditions

- Pressure Rating

- Up to 100 bar (as per application)

- OEM/ODM Service

- Available

- MOQ

- As per order

- Heat Treatment

- Quenched and Tempered (if required)

- Connection Type

- Flanged, Threaded, Welded

Steel Casting Valve Body Trade Information

- Minimum Order Quantity

- 3 Tons

- Supply Ability

- 100000 Tons Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- As Per Buyers Requirement & Order

- Main Domestic Market

- All India

About Steel Casting Valve Body

Vikas Castings is a big name which deals in the manufacturing, supplying and exporting of top quality Valve Body which is manufactured by using advanced casting technologies which results in sturdy and rigid construction that makes it capable to resist impact forces and extreme pressures. It can be used to make a highly durable and reliable flow control system for the industrial flow channels to adjust the flowing rate of the liquid passing through the system.Precision Engineering for Reliable Performance

Our steel casting valve bodies are manufactured using advanced investment casting techniques, ensuring dimensional accuracy within 0.01 mm. This precision creates a robust design that withstands demanding pressure conditions, offering leak-proof sealing and optimal performance in industrial settings.

Versatile Application and Customization

These valve bodies are suitable for a wide range of applications, including water, oil, and gas. With customizable dimensions and connectivity optionsflanged, threaded, or weldedthey are tailor-made to fit your specific needs. OEM and ODM services allow for bespoke design adaptations.

Superior Durability and Corrosion Resistance

Constructed from high-quality steel with excellent machinability, every valve body undergoes surface polishing and optional heat treatment. These features ensure long-term durability and resistance to corrosion, making them a reliable choice for harsh operating environments.

FAQs of Steel Casting Valve Body:

Q: How is the steel casting valve body manufactured to achieve such precise tolerances?

A: The valve bodies are produced using investment casting, a method that enables highly accurate dimensions with a tolerance of 0.01 mm. This precision is maintained through strict quality controls during the casting and machining processes.Q: What types of applications are suited for these steel casting valve bodies?

A: These valve bodies are ideal for water, oil, and gas applications in various industrial settings. Their robust construction and leak-proof sealing make them suitable for systems requiring reliable pressure containment up to 100 bar.Q: When is heat treatment applied during production, and what benefits does it provide?

A: Heat treatment, such as quenching and tempering, is applied when higher strength or toughness is required by the application. This process enhances the mechanical properties and longevity of the valve body under demanding service conditions.Q: Where can these valve bodies be supplied or exported from?

A: We are a manufacturer, supplier, and exporter based in India. Our valve bodies are shipped to industrial clients globally, adhering to ASTM, DIN, or JIS standards or as specified by customers.Q: What is the process for ordering customized dimensions and sizes?

A: Customers can specify their required dimensions (L*W*H), size, and weight during the ordering process. MOQ is flexible according to order, and OEM/ODM services are available for further customization.Q: How does the valve bodys surface treatment contribute to its performance?

A: The polished surface treatment not only gives a smooth, metallic finish but also improves corrosion resistance and ease of maintenance, thereby extending service life and maintaining leak-proof performance.Q: What are the main benefits of using these steel casting valve bodies?

A: Users benefit from robust design, high corrosion resistance, excellent machinability, long service life, and compliance with international standards. Additionally, compatibility with multiple connection types and applications adds further utility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Castings Category

Cast Iron Wedge

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Color : Grey / Black

Surface : Smooth

Material : Other, Cast Iron

Surface Treatment : Polished

Steel Casting Charging Box

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Color : Grey

Surface : Smooth

Material : Other, Highgrade Steel

Surface Treatment : Other, Shot Blasted

Idler Casting

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Color : Natural grey or painted (grey, black, as required)

Surface : Other, Rough, ascast and machined finish

Material : Other, Cast Iron or Cast Steel

Surface Treatment : Other, Shot Blasting

Steel Casting PE Bracket

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Color : Metallic Grey

Surface : Other, Smooth, Corrosion Resistant

Material : Other, High Grade Carbon Steel

Surface Treatment : Other, Hot Dip Galvanized

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry