Steel Casting Crane Wheel

Price 400 INR/ Piece

Steel Casting Crane Wheel Specification

- Surface Treatment

- Coated

- Product Type

- Steel Castings

- Material

- Steel

- Surface

- Polished

- Size

- Standard

- Application

- Crane

- Color

- Silver

Steel Casting Crane Wheel Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- As Per Buyers Requirement & Order

- Main Domestic Market

- All India

About Steel Casting Crane Wheel

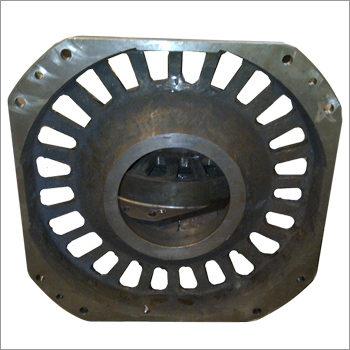

Crane Wheel is most important parts in traveling unit and also is the most vulnerable parts due to the strong impact and wear between wheel and rail. This wheel has very easy installation and simple operation. This wheel is resistant to corrosion and rust proof too. This wheel is available in various sizes and dimensions. Crane Wheel can be produced in virtually any size, configuration and surface finish condition, or in other specifications, as per the requirements of our customers. This wheel is very cost effective and can be easily availed by our esteemed clients at cheaper prices, in bulk quantities.Superior Engineering for Crane Applications

Our steel casting crane wheels are meticulously designed for crane use, featuring advanced casting techniques and a high-quality polished and coated finish. This ensures excellent durability, load capacity, and smooth motion even under stringent operational conditions.

High-Quality Materials and Surface Treatment

Crafted from robust steel, each crane wheel undergoes a specialized polishing and coating process. This not only enhances the wheel's strength and aesthetics but also offers superior resistance to wear and corrosion, extending its operational lifespan.

Trusted Indian Manufacturing and Export

As a leading crane wheel exporter, manufacturer, and supplier in India, we adhere to rigorous quality control protocols. Our products are distributed both domestically and internationally, catering to the diverse requirements of the material handling industry.

FAQ's of Steel Casting Crane Wheel:

Q: How is the steel casting crane wheel manufactured?

A: The steel casting crane wheel is produced using advanced casting techniques, where molten steel is poured into precision molds to achieve the required shape and strength. After casting, the wheels are surface polished and coated for added durability and corrosion resistance.Q: What are the primary applications of this crane wheel?

A: These crane wheels are mainly used in overhead cranes, gantry cranes, and other heavy-duty lifting equipment across industrial environments. Their robustness and surface finish make them ideal for demanding material handling tasks.Q: When should I consider replacing my crane wheel with a new one?

A: It is advisable to replace your crane wheel when you notice signs of wear, flat spots, or surface damage, or if performance is compromised. Regular inspections based on your crane's operational schedule are recommended to ensure optimal safety and functionality.Q: Where can these steel casting crane wheels be used?

A: These wheels are suitable for various environments, including warehouses, construction sites, manufacturing plants, and shipping yards, wherever heavy cranes are in operation.Q: What surface treatments are applied to the crane wheel?

A: Each crane wheel undergoes a specialized polishing and coating process. This dual treatment enhances its surface smoothness, provides a polished silver finish, and offers robust protection against rust and environmental damage.Q: How does the surface finish benefit long-term usage?

A: The polished and coated surface not only improves the wheel's resistance to abrasion and corrosion but also ensures smoother rolling and less maintenance, resulting in cost-effective and reliable long-term performance.Q: What advantages come with sourcing from an Indian manufacturer and exporter?

A: Sourcing from a reputed Indian manufacturer ensures access to globally competitive pricing, stringent quality standards, and reliable customer support-making it an attractive option for both domestic and international buyers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Castings Category

Steel Casting Back Stop

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Weight : 5 kg 1000 kg

Material : Steel

Surface : Other, Rough/Matte

Application : Industrial Machinery, Conveyor Systems

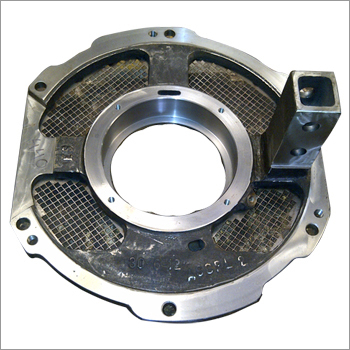

Steel Casting End Frame

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Weight : Varies as per design (typically 100 kg to 500 kg)

Material : Other, High Strength Steel / Mild Steel

Surface : Other, Smooth / Machined

Application : Railway Wagon / Industrial Machinery

Steel Casting PE Bracket

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Weight : 2.5 kg

Material : Other, High Grade Carbon Steel

Surface : Other, Smooth, Corrosion Resistant

Application : Support for Pipe Fittings and Structures

Steel Casting Male Clutch

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Weight : As per Specification/Size

Material : Other, Steel Casting

Surface : Smooth

Application : Industrial Machinery, Automotive, Power Transmission

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry