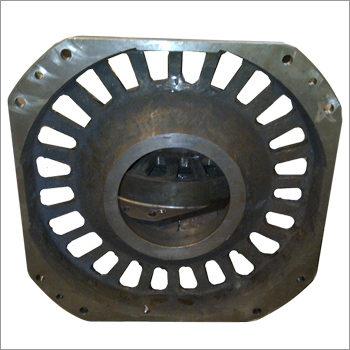

Steel Casting End Frame

Steel Casting End Frame Specification

- Surface Treatment

- Shot Blasted / Painted

- Process

- Sand Casting

- Product Type

- End Frame

- Material

- High Strength Steel / Mild Steel

- Surface

- Smooth / Machined

- Dimension (L*W*H)

- Customized as per requirement

- Size

- Standard / Custom sizes available

- Weight

- Varies as per design (typically 100 kg to 500 kg)

- Application

- Railway Wagon / Industrial Machinery

- Color

- Grey / As per requirement

- Packing

- Wooden Crate / Palletized

- Hardness

- 180-220 HB

- Grade

- IS 2062 / ASTM A27 / Custom

- Corrosion Resistance

- Good, depending on surface treatment

- Casting Method

- Open Mold Sand Casting

- Heat Treatment

- Normalizing / Annealing

- Service Life

- 15-25 years (depending on operating conditions)

- Tolerance

- ±0.5 mm

- Mounting Type

- Bolt-On / Weld-On

- Surface Finish

- Roughness Ra 12.5 max

- Tensile Strength

- 400-600 MPa

Steel Casting End Frame Trade Information

- Minimum Order Quantity

- 2 Tons

- Supply Ability

- 10000 Tons Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- As Per Buyers Requirement & Order

- Main Domestic Market

- All India

About Steel Casting End Frame

An End Frame is used when cast irons cannot deliver enough strength or shock resistance. The offered frame is very useful and made for industrial and commercial applications. The offered frame is made using high quality materials and is used for casting purposes. Casting is one of the oldest manufacturing processes. It is the first step in making most of the products. The offered End Frame is very useful and is made using steel making it highly resistant and durable.Precision Engineering for Heavy-Duty Applications

Our steel casting end frames are engineered with meticulous attention to detail, meeting stringent international standards such as IS 2062 or ASTM A27. Designed for both standard and customized requirements, these components are pivotal in railway wagon construction and heavy machinery, delivering consistent performance under challenging conditions.

Flexible Mounting & Superior Surface Treatments

The product features adaptable mounting optionseither bolt-on or weld-onto suit diverse installation scenarios. Surface treatments, such as shot blasting and painting, enhance corrosion resistance, while machined finishes ensure optimal fit and functionality, even in demanding operating environments.

FAQs of Steel Casting End Frame:

Q: How is the steel casting end frame manufactured?

A: The end frame is produced using open mold sand casting, followed by heat treatment processes like normalizing or annealing to achieve targeted hardness and tensile strength. Surface treatments such as shot blasting or painting are applied to boost corrosion resistance.Q: What application areas are suitable for this steel casting end frame?

A: This product is ideally suited for railway wagons and industrial machinery, where robust mechanical properties and extended service life are essential.Q: When should I opt for a custom size or design?

A: Custom sizes and designs are recommended when specific dimensional, weight, or mounting requirements must be met for unique machinery or wagon configurations. We can manufacture frames with dimensions and weights tailored to your specifications.Q: Where is the product manufactured and exported from?

A: The steel casting end frames are manufactured, supplied, and exported from India, meeting global industry standards for quality and performance.Q: What are the benefits of using this steel casting end frame?

A: You benefit from high strength, good corrosion resistance, flexible mounting options, and a long service life of 1525 years, which contribute to reduced maintenance and operational downtime.Q: Is the surface finish suitable for harsh environments?

A: Yes, surface options like shot blasted or painted finishes and a maximum roughness of Ra 12.5 ensure the end frame can withstand harsh operating conditions, offering excellent durability and protection.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Castings Category

Cast Iron Wedge

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Product Type : Other, Wedge

Application : Machine Alignment, Construction, Industrial Purposes

Surface Treatment : Polished

Material : Other, Cast Iron

Steel Casting Charging Box

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Product Type : Other, Charging Box for Steel Casting

Application : Steel Plant, Foundry, Furnace Charging

Surface Treatment : Other, Shot Blasted

Material : Other, Highgrade Steel

Steel Casting Back Stop

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Product Type : Other, Mechanical Part

Application : Industrial Machinery, Conveyor Systems

Surface Treatment : Other, Shot Blasting

Material : Steel

Steel Casting Grate Ring

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Product Type : Other, Grate Ring

Application : Industrial Furnace, Boiler Grate, Power Plant, Incinerator

Surface Treatment : Polished

Material : Other, High Grade Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry