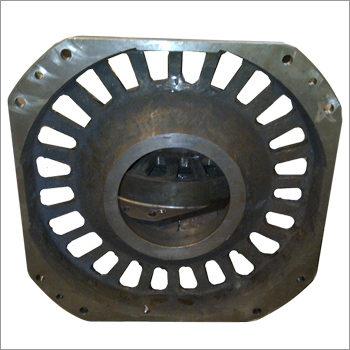

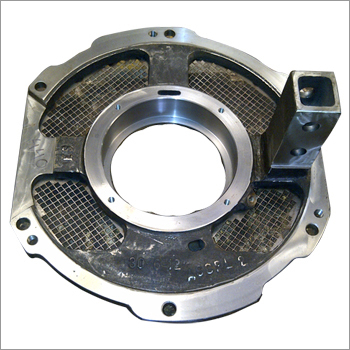

Steel Casting Grate Ring

Steel Casting Grate Ring Specification

- Surface Treatment

- Polished

- Process

- Sand Casting

- Product Type

- Grate Ring

- Material

- High Grade Steel

- Surface

- Smooth/Anti-corrosive

- Dimension (L*W*H)

- Custom as per requirement

- Size

- Standard/Custom

- Weight

- Varies per dimension (typically 10-50 kg)

- Application

- Industrial Furnace, Boiler Grate, Power Plant, Incinerator

- Color

- Metallic Grey

- Casting Tolerance

- 2 mm

- Standard Packaging

- Wooden crates or as per customer requirement

- Finish

- Machined or as cast

- Shape

- Ring / Circular

- Tensile Strength

- 420 485 MPa

- Heat Resistance

- Up to 800C

- Corrosion Resistance

- Moderate, can be improved with coatings

- Hardness

- 150 220 HB

- Grade

- ASTM A216 or equivalent

- Compatibility

- Suitable for various furnace and boiler models

Steel Casting Grate Ring Trade Information

- Minimum Order Quantity

- 2 Tons

- Supply Ability

- 100000 Tons Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- As Per Buyers Requirement & Order

- Main Domestic Market

- All India

About Steel Casting Grate Ring

Grate Rings are the advanced solutions, which can be used with a cooking grate. They can be adjusted as per the application needs. The said products are appreciably for their high functionality and high utility. Grate Rings are highly robust and extensively durable solutions, appreciable for their uniform size and consistency in function. By making use of these rings, advantages can be maximized. They are made to absorb the heat rapidly. The rings can be used with the waterproof membranes.Optimized Design for Industrial Reliability

Our steel casting grate rings are meticulously crafted in a ring or circular design to ensure optimal performance in furnaces, boilers, and power plants. The robust construction and precise 2 mm casting tolerance guarantee a secure fit and consistent operation, even under intense heat and pressure.

Superior Heat and Corrosion Resistance

Built to handle continuous exposure to high temperatures up to 800C, these rings maintain structural integrity in demanding environments. The base corrosion resistance is adequate for most applications and can be further improved with specialized coatings to extend service life in harsh conditions.

Customizable for Versatile Applications

We offer both standard and custom dimensions and weights (typically 1050 kg) to accommodate various equipment models. Our products are available with a polished finish and a choice of as-cast or machined surfaces, all manufactured using proven sand casting processes for dependable quality.

FAQs of Steel Casting Grate Ring:

Q: How is the steel casting grate ring manufactured?

A: The grate ring is produced using the sand casting process, followed by machining and polishing if required. This ensures a smooth, anti-corrosive surface and precise dimensional accuracy suitable for industrial applications.Q: What applications are suitable for this grate ring?

A: This product is ideal for use in industrial furnaces, boiler grates, power plants, and incinerators, thanks to its heat resistance, structural strength, and compatibility with various equipment models.Q: What benefits does the ASTM A216 grade steel provide?

A: ASTM A216 grade steel offers excellent tensile strength (420485 MPa) and heat tolerance up to 800C, providing reliability and longevity for critical operations in harsh environments.Q: When should anti-corrosive coatings be applied to the grate ring?

A: Anti-corrosive coatings should be applied when the grate ring will operate in highly corrosive settings or where exposure to moisture or aggressive chemicals is anticipated, enhancing durability and lifespan.Q: Where can you install these grate rings?

A: These rings are designed for installation in a wide range of industrial equipment, particularly in areas requiring heat and wear resistancesuch as combustion chambers, boiler beds, and waste incinerators.Q: How does the packaging ensure the safe delivery of grate rings?

A: Grate rings are typically packed in sturdy wooden crates or as per specific customer instructions, providing protection during transportation and handling to prevent physical damage or surface defects.Q: What is the typical weight and dimension range available?

A: The weight of each steel grate ring typically ranges from 10 to 50 kg, and both standard and custom dimensions are available to match your specific requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Castings Category

Steel Casting End Frame

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Surface Treatment : Other, Shot Blasted / Painted

Color : Grey / As per requirement

Surface : Other, Smooth / Machined

Steel Casting Anode Bracket

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Surface Treatment : Other, Hot Dip Galvanized

Color : Metallic Grey

Surface : Smooth

Idler Casting

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Surface Treatment : Other, Shot Blasting

Color : Natural grey or painted (grey, black, as required)

Surface : Other, Rough, ascast and machined finish

Steel Casting PE Bracket

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Surface Treatment : Other, Hot Dip Galvanized

Color : Metallic Grey

Surface : Other, Smooth, Corrosion Resistant

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry