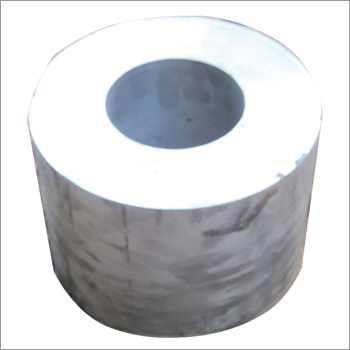

Steel Segment Casting

Steel Segment Casting Specification

- Process

- Casting

- Surface Treatment

- Polished

- Product Type

- Steel Segment

- Material

- High-strength Alloy Steel

- Surface

- Smooth

- Dimension (L*W*H)

- Customizable (Standard: 500mm x 250mm x 100mm)

- Size

- Standard, Customized sizes available

- Weight

- Approx. 75 kg per segment

- Application

- Tunnel lining, Infrastructure, Construction

- Color

- Metallic Grey

- Packing Type

- Wooden pallets or steel frames

- Service Life

- Up to 50 years

- Usage Environment

- Underground, High load-bearing

- Tolerance

- ±2 mm

- Corrosion Resistance

- High

- Shape

- Segmented curve

- Impact Strength

- Superior

- Hardness

- 220-250 HB

- Grade

- EN 10025 S355JR / ASTM A36

Steel Segment Casting Trade Information

- Minimum Order Quantity

- 2 Tons

- Supply Ability

- 10000 Tons Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- As Per Buyers Requirement & Order

- Main Domestic Market

- All India

About Steel Segment Casting

The offered Segment is made available by us for being used in casting. It is very efficient and strong. It will be cast against, ensuring a perfect and unique connection match-cast face. It is a semi-continuous vertical casting process, which is widely used for the production of nonferrous alloys. It is made for industrial purposes and is highly demanded due to its strength and use in the casting processes. Segment Casting is a semi-continuous vertical casting process.Superior Strength and Longevity

Crafted from high-strength alloy steel and processed via precision casting, our segments meet stringent specifications for impact durability and load-bearing capacity. The polished surface ensures minimal friction and is highly resistant to corrosion. Once installed, these segments contribute significantly to the structural safety of tunnels and underground constructions.

Customizable Solutions for Challenging Environments

Recognizing the variety of project requirements, we offer both standard and customizable sizes to meet specific architectural and engineering needs. With a tolerance of 2 mm, every segment is tailored for efficient fitment and installation, especially in high-stress underground environments where reliability and safety are paramount.

FAQs of Steel Segment Casting:

Q: How are steel segment castings with EN 10025 S355JR / ASTM A36 grades used in underground tunnel construction?

A: Steel segment castings serve as critical reinforcements for tunnel linings, providing superior load-bearing and impact resistance. Their curved, segmented shape forms a tight fit, distributing stress evenly to ensure long-lasting stability in demanding underground conditions.Q: What process is involved in manufacturing these steel segment castings?

A: These segments are manufactured through advanced casting methods using high-strength alloy steel, followed by precision polishing to achieve a smooth surface. Each item undergoes strict quality checks to meet specified hardness and tolerance requirements.Q: When should custom dimensions be selected instead of the standard size?

A: Custom dimensions are recommended when project specifications differ from the standard segment size of 500mm x 250mm x 100mm. Tailoring the size ensures compatibility with unique tunnel geometries or specific infrastructure needs for optimal installation.Q: Where is this steel segment casting product typically applied?

A: These castings are commonly used for tunnel linings, infrastructure reinforcement, and construction projects requiring robust, durable components with excellent corrosion resistance and long service life.Q: What are the main benefits of using these castings in high load-bearing environments?

A: The primary benefits include exceptional impact strength, high corrosion resistance, and a service life up to 50 years. Their resilience ensures safety and reduces maintenance, making them ideal for underground, high-stress conditions.Q: How is the surface of the segment castings treated, and why is this important?

A: Segments are polished to a smooth finish, which reduces friction and enhances corrosion resistance. This surface treatment supports longevity, making the segments well-suited for environments where moisture and stress are prevalent.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Castings Category

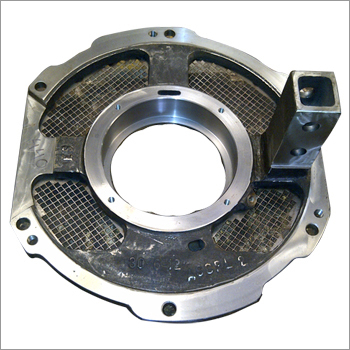

Steel Casting Hub Assembly

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Application : Automobile, Industrial Machinery

Dimension (L*W*H) : According to customer drawing/specification

Product Type : Other, Hub Assembly

Weight : 830 kg

Steel Casting Back Stop

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Application : Industrial Machinery, Conveyor Systems

Dimension (L*W*H) : Customized

Product Type : Other, Mechanical Part

Weight : 5 kg 1000 kg

Steel Casting Bridge Bearing Casting

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Application : Bridge Construction, Structural Support

Dimension (L*W*H) : Customized as per drawing

Product Type : Other, Bridge Bearing Casting

Weight : Depends on design (typically 50500 kg)

Steel Casting PE Bracket

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Application : Support for Pipe Fittings and Structures

Dimension (L*W*H) : 150 mm x 80 mm x 50 mm

Product Type : Other, PE Bracket

Weight : 2.5 kg

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry