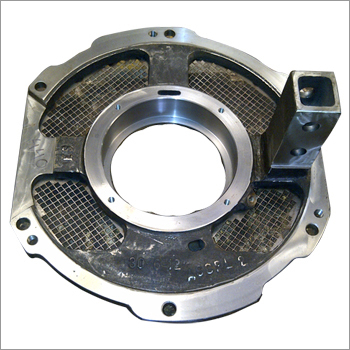

Steel Casting Bridge Bearing Casting

Steel Casting Bridge Bearing Casting Specification

- Process

- Sand Casting

- Surface Treatment

- Shot Blasted

- Product Type

- Bridge Bearing Casting

- Material

- Steel

- Surface

- Smooth

- Dimension (L*W*H)

- Customized as per drawing

- Size

- Standard / Customized

- Weight

- Depends on design (typically 50-500 kg)

- Application

- Bridge Construction, Structural Support

- Color

- Metallic Grey

- Packaging

- Wooden Cases / as requested

- Yield Strength

- Minimum 250 MPa

- Impact Value

- Minimum 20 J (Charpy)

- Finish Type

- Machined

- Tensile Strength

- Minimum 450 MPa

- Standard

- ASTM A27 / IS 1030

- Tolerance

- 0.2 mm

- Corrosion Resistance

- High (with protective coating)

- Service Life

- 30 Years

- Installation

- Bolt/Fix as per Structural Engineering Design

- Hardness

- 170-220 HB

Steel Casting Bridge Bearing Casting Trade Information

- Minimum Order Quantity

- 2 Tons

- Supply Ability

- 100000 Tons Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- As Per Buyers Requirement & Order

- Main Domestic Market

- All India

About Steel Casting Bridge Bearing Casting

Bridge Bearing Casting manufactured and supplied by us is designed as per the industrial standards by using highly durable and sturdy engineering materials that makes it capable to withstand extreme loads and harsh environmental conditions for longer service life. This bearing support element is designed and developed with high precision which gives excellent dimensional accuracy and structural stability. It is available at a rate of 85 to 500 rupees per Kilograms with a supply capacity of 1000 Kilograms per month.Exceptional Mechanical Performance

Steel casting bridge bearings are meticulously engineered to offer robust performance under demanding conditions. Their superior tensile strength, yield strength, and impact value ensure optimal load distribution and longevity, making them ideal for heavy-duty infrastructural projects. The advanced machining and shot blasting treatments result in a smooth, reliable surface finish with tight tolerances.

Tailored Solutions for Diverse Projects

Each bearing is available in standard or customized dimensions and weights, ranging from 50 to 500 kg. Manufacturers work closely with clients to produce castings that fit structural requirements, ensuring precise installation. All units undergo rigorous quality checks and are delivered in protective wooden cases or as specified by the client, guaranteeing damage-free transit and simple, secure application.

Durability and Corrosion Resistance

With a service life of over 30 years, these bridge bearing castings feature a high level of corrosion resistance thanks to protective coatings and high-grade steel. The design philosophy prioritizes longevity even in challenging environments, reducing the need for frequent maintenance and ensuring the structural integrity of bridges and other civil engineering projects.

FAQs of Steel Casting Bridge Bearing Casting:

Q: How are steel casting bridge bearings installed in bridge structures?

A: Installation is typically performed by bolting or fixing the bearings onto the bridge framework as per structural engineering design. Experienced professionals ensure that the castings are accurately aligned and secured for optimal load transmission and stability.Q: What advantages does the protective coating provide for corrosion resistance?

A: The protective coating effectively shields the steel surface from moisture, chemicals, and environmental pollutants. This high level of corrosion resistance helps maintain the bearings integrity and reduces maintenance costs over its service life, especially in harsh outdoor conditions.Q: When should these bridge bearing castings be used in construction projects?

A: These bearings are recommended for new bridge construction, infrastructure upgrades, or replacements where high load-bearing capacity, longevity, and precision are crucial. They support both dynamic and static loads in various structural support applications.Q: Where are these steel castings manufactured and supplied from?

A: They are produced and exported by accredited manufacturers and suppliers in India, with the capacity to serve both domestic and international markets. Quality standards like ASTM A27 and IS 1030 are rigorously followed.Q: What is the manufacturing process for these bridge bearings?

A: The castings are produced through sand casting, followed by shot blasting for surface preparation and machining for dimensional accuracy. This process ensures a smooth surface finish, tight tolerances, and the required mechanical properties.Q: How does customization work for dimensions and sizes?

A: Clients provide detailed drawings or specifications, and the manufacturer tailors the casting dimensions, sizes, and weights accordingly. This flexibility allows for integration into a wide range of bridge designs and structural requirements.Q: What are the main benefits of using these steel casting bridge bearings?

A: Key benefits include high mechanical strength, reliable corrosion resistance, long service life (over 30 years), and the ability to customize for project-specific needs. Their precise fabrication and robust design help ensure structural safety and durability in demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Castings Category

Steel Casting Male Clutch

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Surface Treatment : Polished

Color : Metallic Silver

Process : Precision Casting

Size : Standard and Custom Sizes Available

Steel Casting PE Bracket

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Surface Treatment : Other, Hot Dip Galvanized

Color : Metallic Grey

Process : Precision Steel Casting

Size : Standard

Steel Casting Charging Box

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Surface Treatment : Other, Shot Blasted

Color : Grey

Process : Sand Casting

Size : Standard / Customizable

Steel Casting Grate Ring

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Surface Treatment : Polished

Color : Metallic Grey

Process : Sand Casting

Size : Standard/Custom

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry