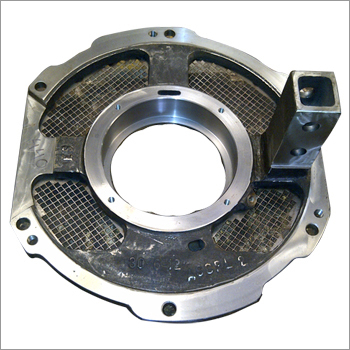

Steel Casting Air Valve Body

Steel Casting Air Valve Body Specification

- Process

- Precision Casting

- Surface Treatment

- Sand Blasted

- Product Type

- Valve Body

- Material

- Alloy Steel

- Surface

- Smooth Finish

- Dimension (L*W*H)

- 240mm x 150mm x 180mm

- Size

- 2 inch To 24 inch

- Weight

- 6 Kg - 150 Kg

- Application

- Industrial Air Release Valve

- Color

- Metallic Grey

Steel Casting Air Valve Body Trade Information

- Minimum Order Quantity

- 2 Tons

- Supply Ability

- 10000 Tons Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- As Per Buyers Requirement & Order

- Main Domestic Market

- All India

About Steel Casting Air Valve Body

The offered Air Valve Body is made available by us is one of the pieces of equipment that allows an automatic transmission to function correctly. The transmission depends on the transmission valve body more than any other component. It is directly linked to the transmission computer for the purpose of regulating the flow of transmission fluid to different hydraulic valves within the transmission. The offered body is very efficient and strong. The Air Valve Body is very durable and effective.Reliable Performance Across Challenging Conditions

Designed to withstand pressures up to 25 Bar and temperatures between -20C to 450C, this air valve body ensures consistent operation in various industrial environments. The anti-rust coating and precision casting process provide enhanced durability and resistance to corrosion, making it suitable for use with air, gas, and water.

Precision-Engineered for Optimal Efficiency

Manufactured to ASTM A216/A351 standards, the valve body features a flanged end connection for secure installation. Every product is ultrasonically and hydraulically tested, with strict adherence to a 0.2 mm casting tolerance. The sand-blasted, smooth surface finish not only promotes efficient flow but also improves longevity.

Versatile Sizing and Dependable Quality

Available in a wide range of sizes, from 2 inches to 24 inches and in weights from 6 kg to 150 kg, this air valve body adapts to diverse industrial requirements. Its metallic grey color and robust alloy steel construction make it an ideal choice for air release valve systems across multiple industries.

FAQs of Steel Casting Air Valve Body:

Q: How does the Steel Casting Air Valve Body ensure a leakage-proof operation?

A: Each valve body undergoes rigorous ultrasonic and hydraulic testing, ensuring that it meets the highest standards for 100% leakage-proof performance in industrial air release applications.Q: What process is used to manufacture the air valve body, and why is it beneficial?

A: The air valve body is produced using the precision casting method. This process enables accurate dimensional control (0.2 mm), results in a smooth surface finish, and ensures reliable mechanical properties for industrial usage.Q: When should the Steel Casting Air Valve Body be used in an industrial setup?

A: This product is recommended for use in air release valve systems that experience operating pressures up to 25 Bar and temperatures between -20C and 450C with media such as air, gas, or water.Q: Where is this valve body commonly installed?

A: It is typically fitted in industrial facilities, plants, and infrastructure where efficient air release and corrosion resistance are critical, particularly in fluid transport pipelines.Q: What are the benefits of the anti-rust coating applied to the valve body?

A: The anti-rust coating significantly extends the products lifespan by preventing oxidation and surface deterioration, ensuring reliable performance even in harsh environmental conditions.Q: Is the Steel Casting Air Valve Body compatible with different media types?

A: Yes, the valve body is suitable for use with air, gas, and water due to its robust alloy steel construction and corrosion-resistant surface treatment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Castings Category

Steel Casting Anode Bracket

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Application : Cathodic Protection Systems

Product Type : Other, Anode Bracket

Color : Metallic Grey

Surface : Smooth

Steel Casting PE Bracket

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Application : Support for Pipe Fittings and Structures

Product Type : Other, PE Bracket

Color : Metallic Grey

Surface : Other, Smooth, Corrosion Resistant

Cast Iron Coupling

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Application : Pipe fitting and plumbing connections

Product Type : Other, Pipe Coupling

Color : Black / Silver Grey

Surface : Smooth

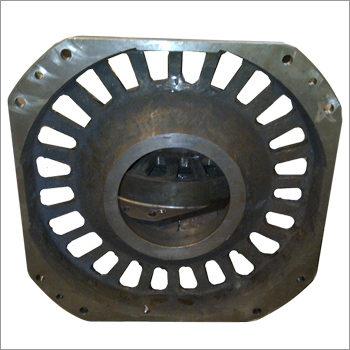

Steel Casting End Frame

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Application : Railway Wagon / Industrial Machinery

Product Type : Other, End Frame

Color : Grey / As per requirement

Surface : Other, Smooth / Machined

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry